WHAT IS

DECORATIVE PANEL

Decorative Panels decorative insulation panels are sandwich panels produced for use in both indoor and outdoor environments. Beyond being a decorative architectural finishing product, it provides thermal, fire, and sound insulation. It offers practical solutions for partition walls and suspended ceilings in addition to being applied to existing walls indoors. The top layer of aluminum or galvanized steel is covered with a nanotechnology protective layer, the middle part is a polyurethane insulation layer, and the bottom part is an aluminum foil layer.

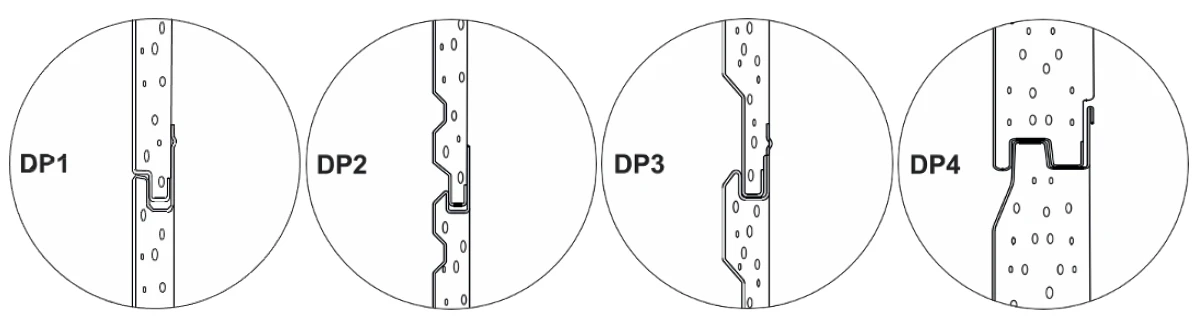

It offers a variety of surface textures, with options for wood, marble, and wallpaper appearances. Production can be done in desired lengths up to 6 meters. Panels with a thickness of 10 mm can be used both indoors and outdoors, while panels with a thickness of 30 mm can be used on exterior facades. Our production line can produce panels in four different sections and various widths.

Why Decorative Panels?

When applied to walls and ceilings in intermediate floors and attic floors of buildings, it provides a temperature difference of 7 degrees. It plays a significant role in thermal insulation, preventing the interior from heating up in regions where external temperatures are very high and maintaining interior heat in regions where external temperatures are very low, providing a comfortable living environment.

Provides up to 29 dB noise reduction. This feature significantly contributes to sound insulation in buildings requiring sound insulation such as hospitals, hotels, schools, laboratories, and office buildings.

The product meets the properties of B1 non-combustibility class. STRENGTH: The product, composed of the combination of aluminum or galvanized steel alloy sheet and polyurethane material, has a structure that is not easily damaged. It can be applied to all kinds of ceilings and walls without causing deformation or sagging.

Prevents the formation of cold surfaces and thus dampness and moisture in walls and ceilings caused by temperature differences.

The material does not contain any harmful raw materials to the environment. It does not release any toxic gases. It is not harmful to the health of people living in the environments where it is used.

In addition to being applicable to all existing walls and ceilings, it replaces many material applications in partition wall and suspended ceiling applications, maximizing savings in labor and time; it is an innovative coating material. Compared to other traditional wall and ceiling materials, its very light structure does not contribute to earthquake load in buildings. It is easy to transport and install.

Much more resistant to deformation and aging compared to alternative decoration materials. The surface is easy to clean and does not retain dirt.

Adds value to the environment where the material is used, offering interior architectural design possibilities suitable for every structure thanks to its variety of exterior appearances.

No chassis is needed in material application; it can be applied directly to the wall using screws or staples, saving 5-10 cm of wall space.

Product Features

- New Generation

- Thermal Insulation

- Sound Insulation

- Fire Insulation

- Strength

- Moisture-Proof

- Environmental Protection

- Easy Installation

Technical Specifications

Decorative insulation panels covered with nano protective film, made by combining colored and patterned aluminum or galvanized steel sheet with polyurethane foam material and aluminum foil, having a thermal conductivity coefficient of 0.024 W/m K, meeting B1 non-combustibility class conditions, produced in thicknesses ranging from 10 to 30 mm, widths from 150 to 450 mm, and lengths up to a maximum of 6000 mm, for various cross-sections and surface textures for both indoor and outdoor use.

Dimensions and Values Related to Our Product

| Features | Value |

|---|---|

| Material description | Decorative Insulated Composite Panel |

| Thickness | 10 mm–30 mm |

| Width | 150 mm–450 mm |

| Length | Max – 6000 mm |

| Joint | Applicable sealant depending on detail and thickness |

| Thermal Conductivity Coefficient | 0.024 W/mK |

| Layers | Aluminum (ALU) or painted galvanized sheet (PPGS) + Polyurethane foam (PU) + Aluminum |

| UV Guarantee | 10 years |